POLY GROUT

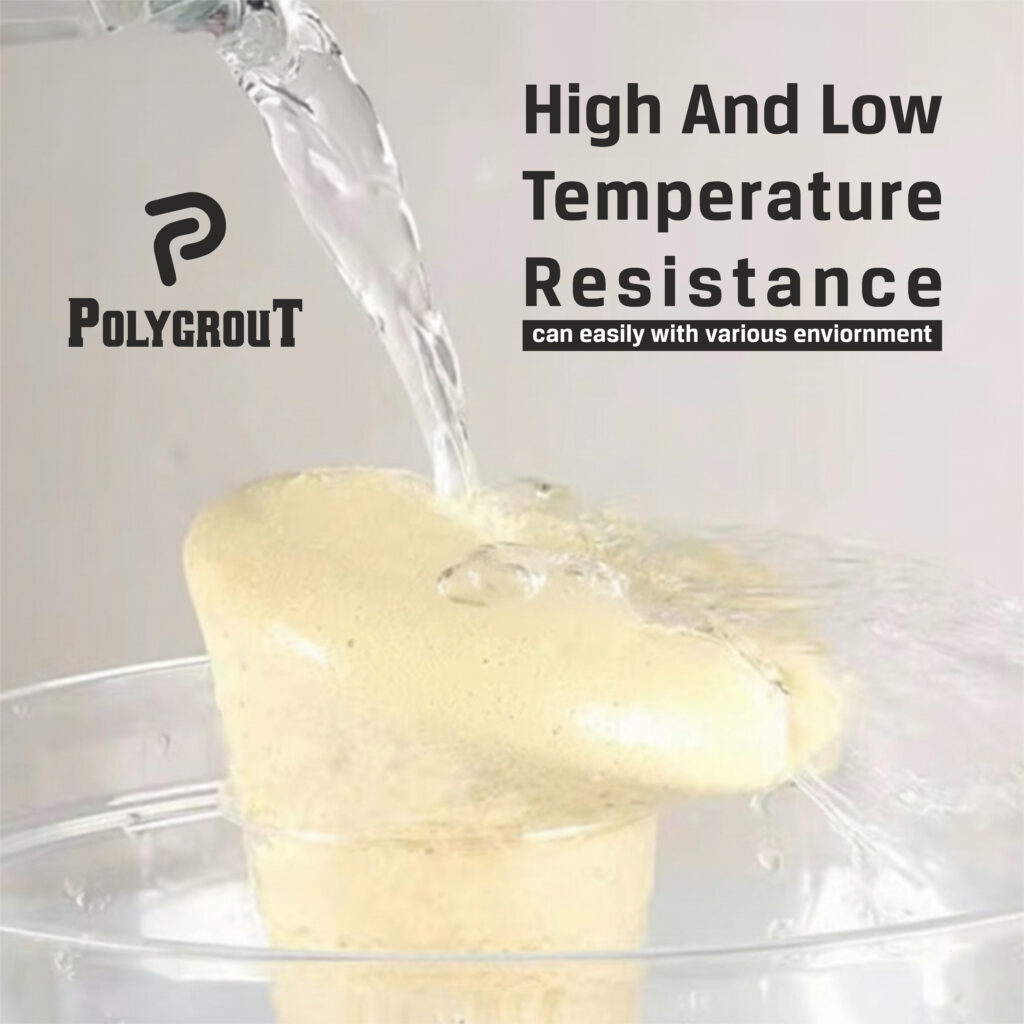

CrackExperts Polygrout is a highly effective, hydrophobic grout based on polyurethane. Upon contact with water, it reacts to form a closed-cell, semi-rigid foam expanding its volume by 3000%.

Category: Products

Description

CrackExperts Polygrout is a hydrophobic grout based on polyurethane. Upon contact with water, it reacts to a closed-cell, semi-rigid foam while expanding its volume up to 3000%.

The cured material maintains a constant volume and is not affected by water or dryness, ensuring the reacted material does not shrink or swell.

Technical Properties

| Property | Value |

|---|---|

| Form | Liquid Type |

| Color | Dark Brown |

| Solubility in Water | Hydrophobic |

| Density | 1.18 g/ml |

| Viscosity | 100-200 |

| Max. Expansion (25°C) | 2,700% (Ratio 10:1 Resin: Water) |

| Induction Time (25°C) | 15 sec (Ratio 2:1 Resin: Water) |

| Gel Time (25°C) | 110 sec (Ratio 2:1 Resin: Water) |

| Tensile Shear Strength (23°C) | 4 N/mm² |

| Appearance | Light Yellow Polyurethane Foam |

| Corrosiveness | Non-Corrosive |

| Chemical Resistance | Resistant to most organic Solvent, Mild Acids, Alkali |

Features / Advantages

- Negative side application possible

- Deep penetration into very small cracks

- Foam increases in volume to fill cavities and voids

- Excellent bond to surfaces

- Good adhesive strength, tolerant of movement

- Inert after curing, constant volume, no shrinkage

- Does not create new cracks

Areas of Application

- Defective concrete (cracked or honeycombed)

- Concrete joints, Limestone, Brick construction

- Pipe intrusions, Waste water tanks

- Tunnels, Dams, Subway (Metro), Sewers, Manholes, Utility boxes, etc.

- Soil stabilization

Application Process

- Check Crack Area: Check crack area and clean up the surface with a wire brush or grinder.

- Drill Holes: Drill holes near cracks using a hammer drill, with a 45° angle from the surface, to prevent packers from penetrating through a crack.

- Position IT ZIGZAG & Distance: Hole positions must be zigzag, with a separation gap of 15-20 cm from each other.

- Keep 15-20cm Distance : Make a hole as per the image 2 & 3 each separated by gap 15-20 from each othercm

- Insert Packers: Insert packers into the drilled holes and fasten them tightly using a T-wrench.

- PU Injection (Polygrout) Prep: Pour the PU Injection (Polygrout) into the plastic bottle.

- Connect the Coupler: Connect the grease coupler with the installed packer. Inject first at the low area, and then move to the upper area (down to up).

- Inject PU Resin: Push the switch for the running machine and inject PU resin into a hole. Start with low pressure and increase. When PU resin flows out from the cracks, stop injection, move to another packer, and start injection again.

- Remove Packers: After finishing injection, remove packers by hitting them with a hammer. Clean the surface using a scraper or a grinder, and if needed, coat with sealing materials. Damaged areas can be sealed with polymer modified mortar.

- Clean the Machine: Clean the machine properly using xylene thinner. Pour the Xylene thinner in the jar of the grouting machine and follow the cleaning procedure.

Shelf Life

- 1 Year in tightly sealed container.

- Stored at a temperature of 0 to $30^{\circ}C$ from date of import.

- Up to 3 months for reuse on opening the seal, provided the material is kept in a closed container free from moisture.

Watch the Application Video

Related products

-

CRACKFIX PU 35

Read moreCrackFix PU 35 is a high-strength, fast-cure polyurethane sealant designed for high-requirement bonding and sealing applications. It offers excellent wear and weather resistance and maintains performance across a wide range of temperatures.

-

UV SHIELD PRO

Read moreThis list outlines various product categories focused on sustainability, non-toxicity, and improved indoor air quality, providing healthier alternatives to conventional consumer and building materials.